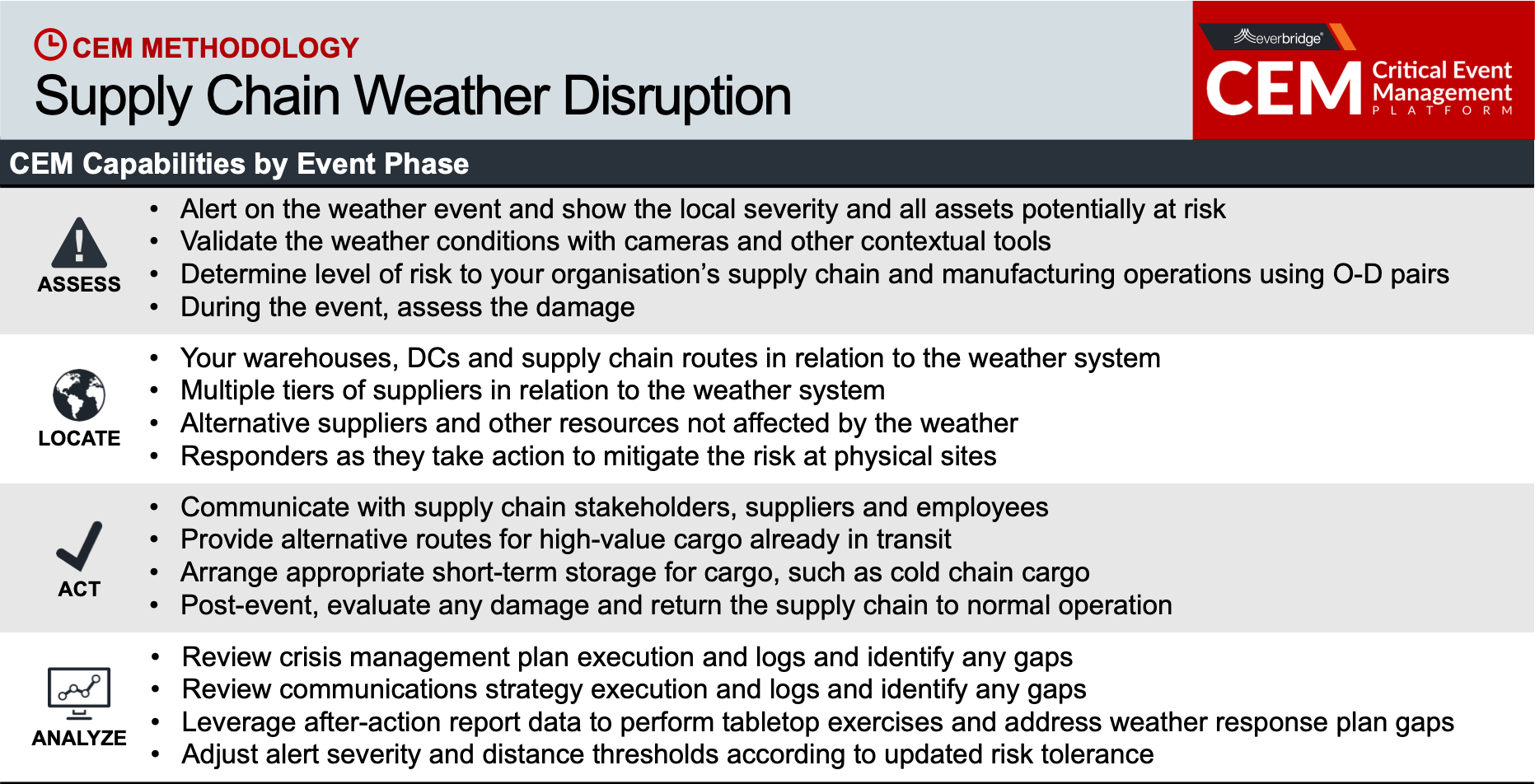

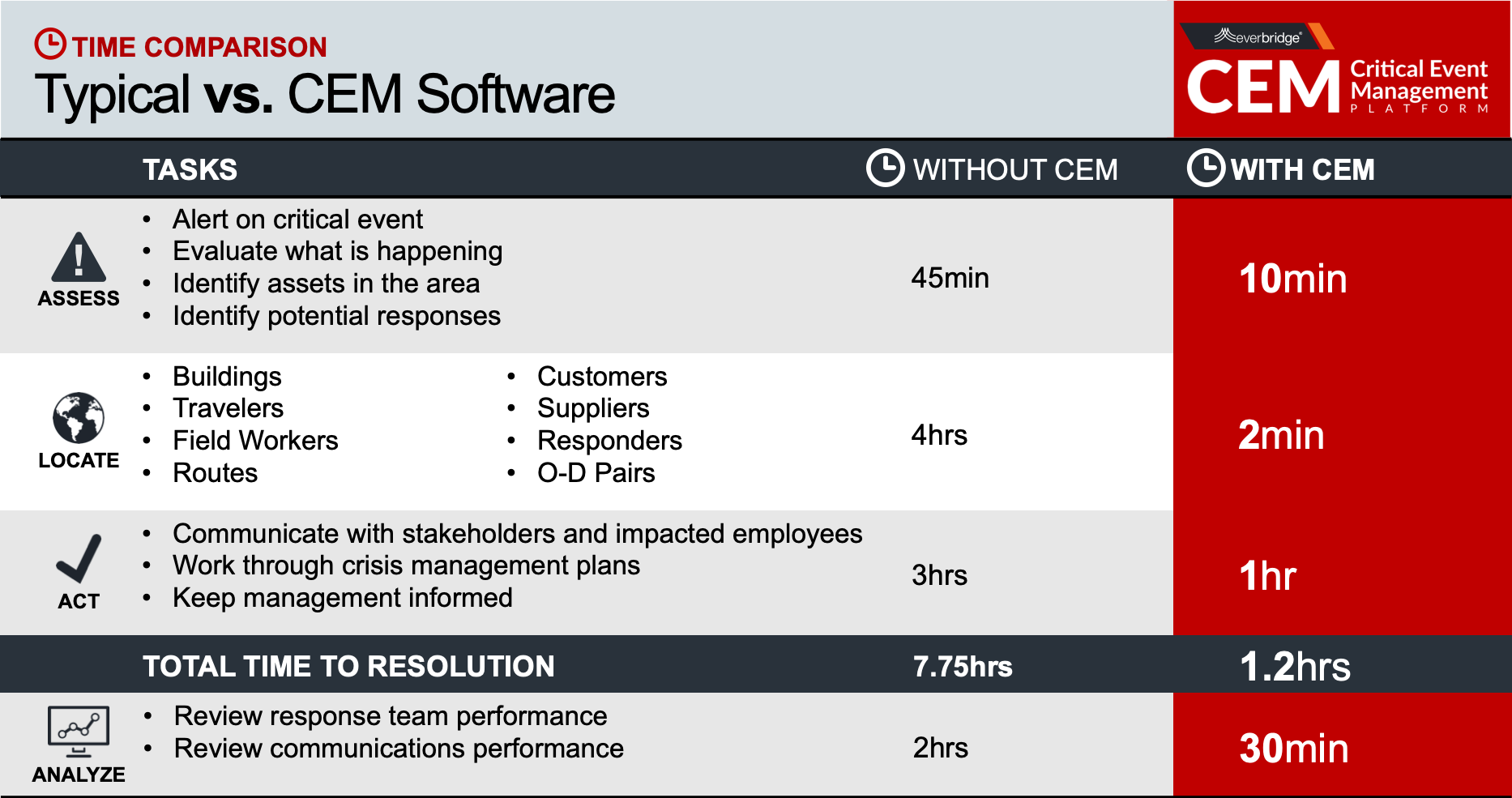

Weather Impacting Supply Chain (Europe)

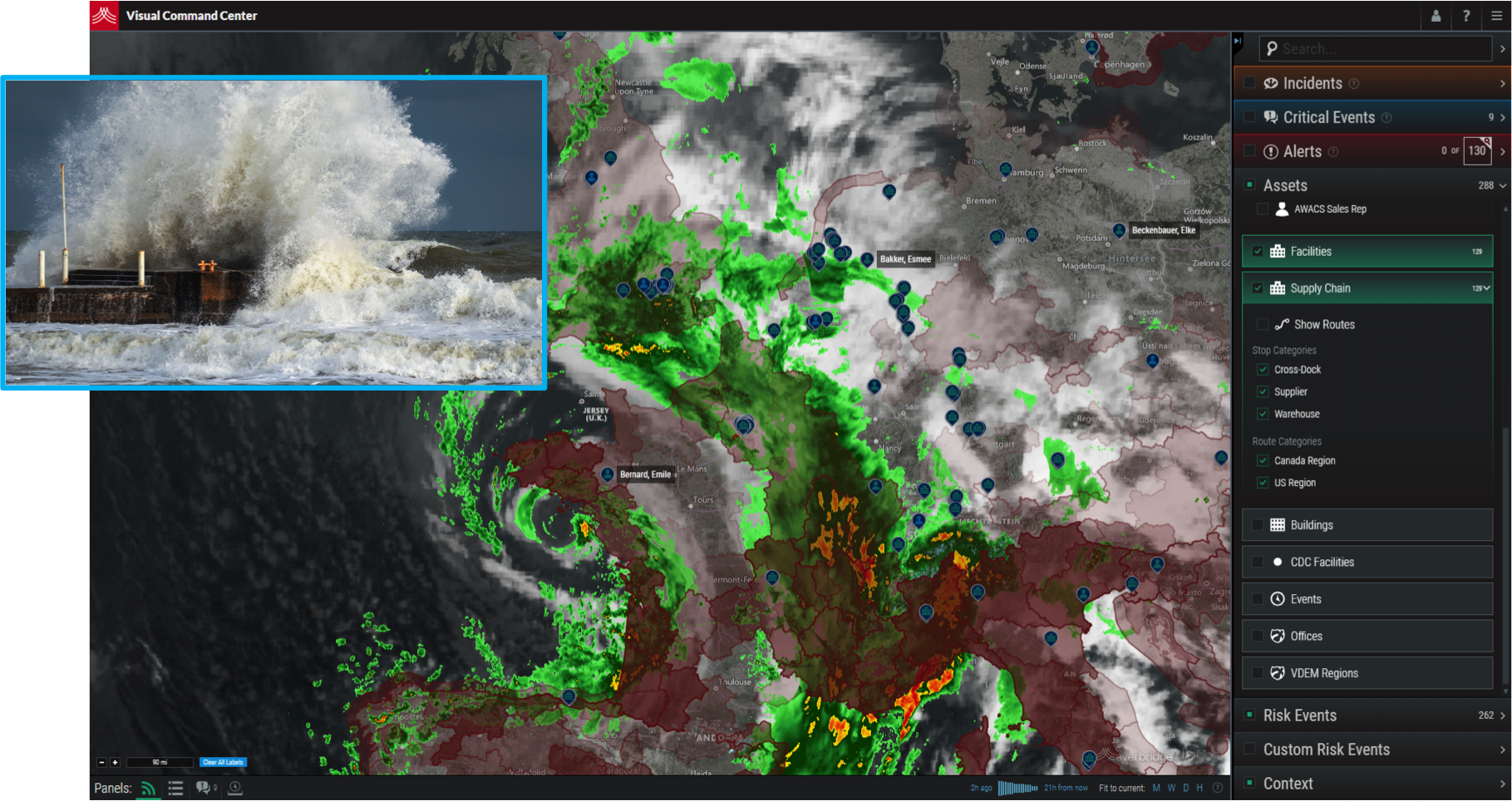

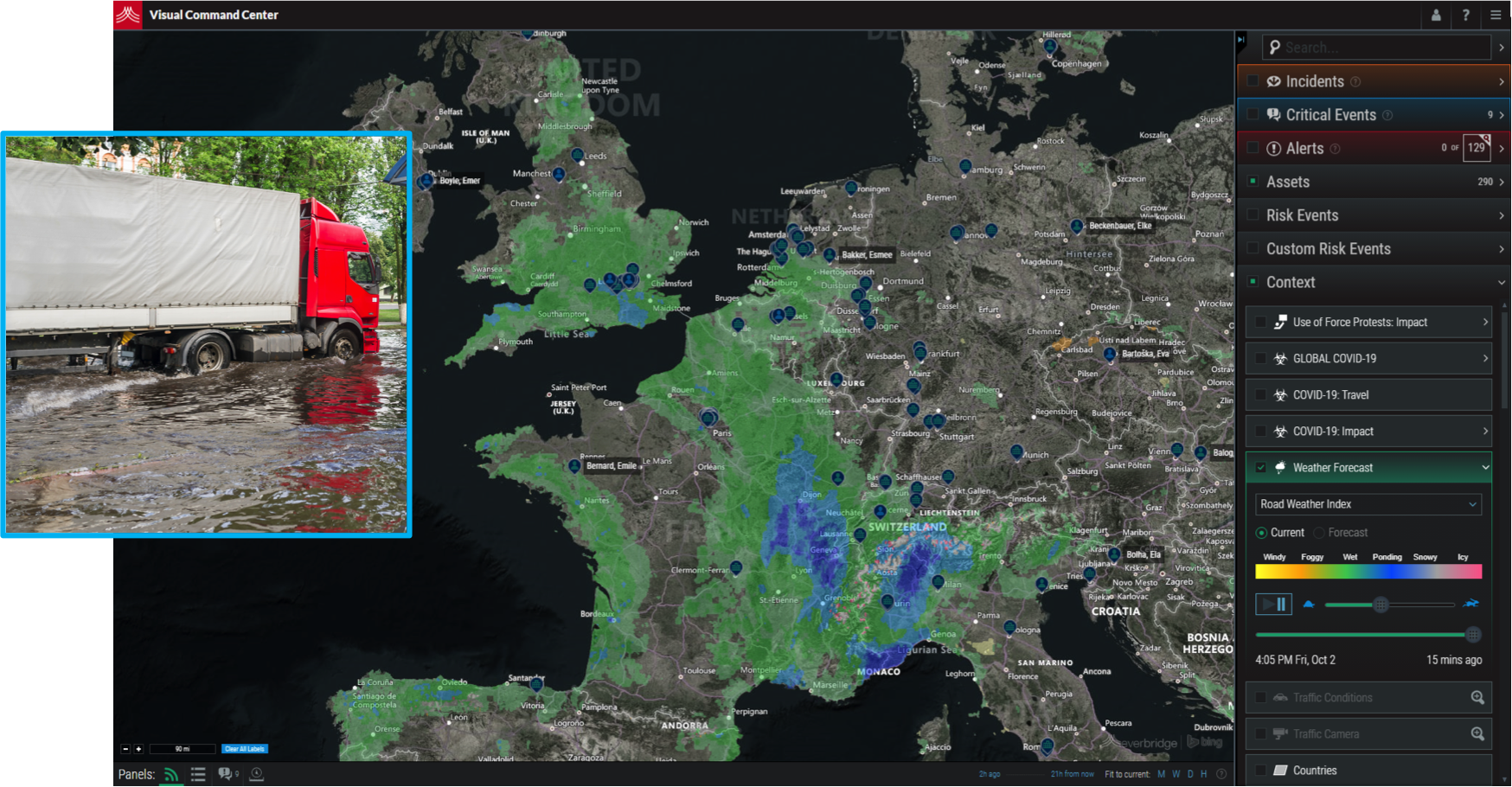

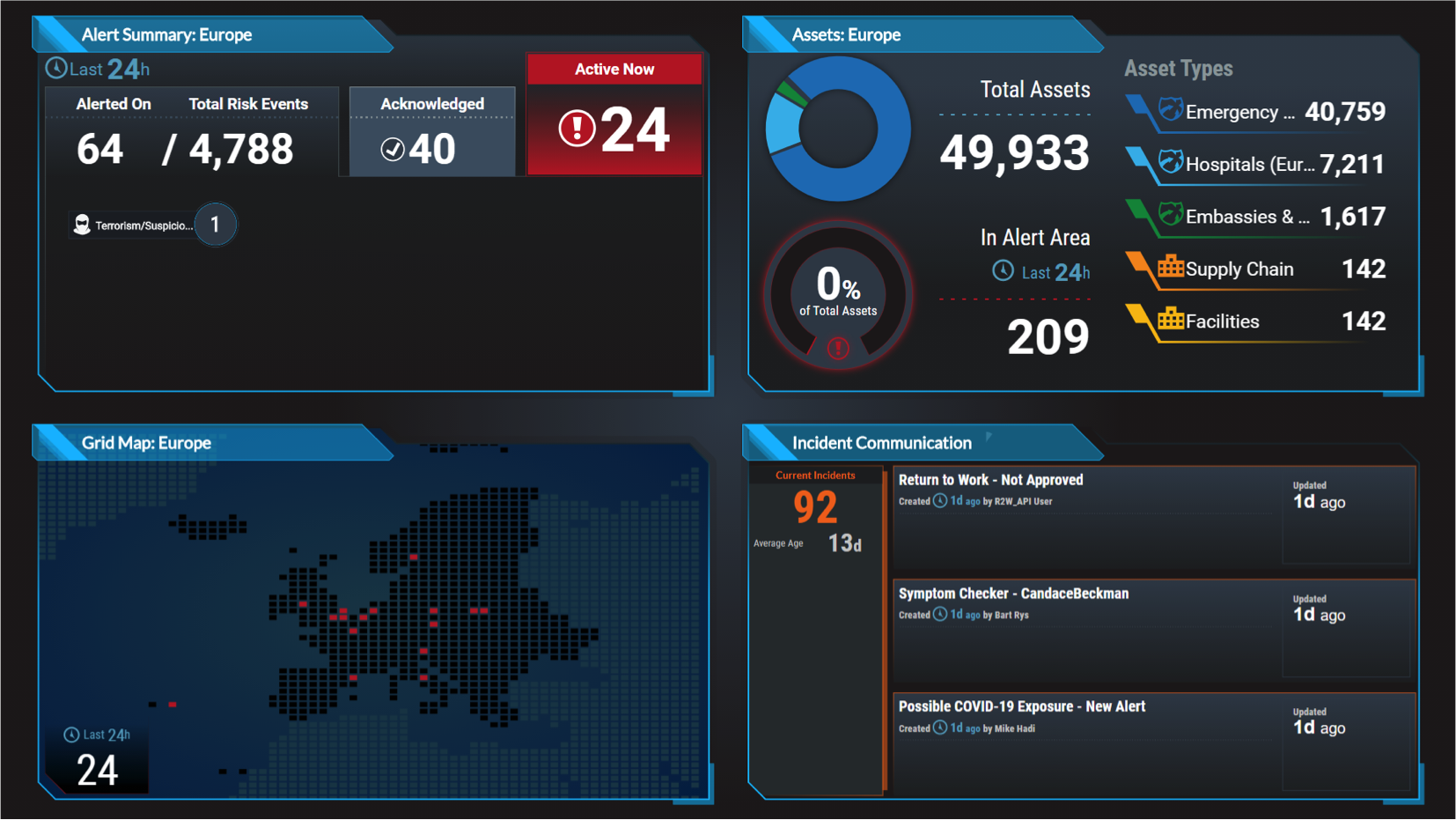

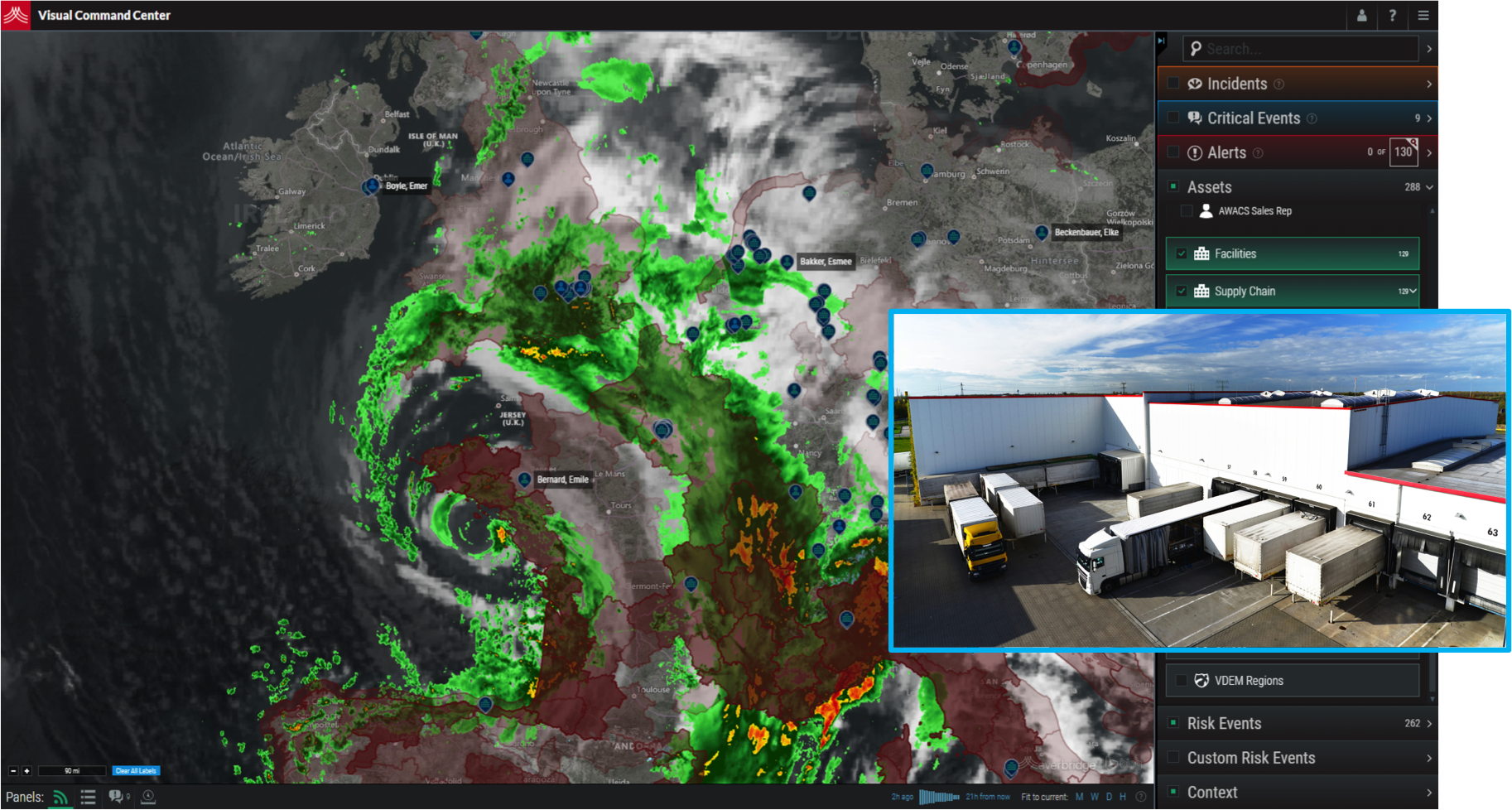

Your team monitors a major North Atlantic storm. The storm generates excessive wind, rain, and flood alerts across the European operating region. Everbridge automatically identifies and locates your facilities, people, suppliers and supply routes in relation to the storm.

Recent similar storms have led to tidal surges and widespread flooding. Disruption to ports and overland shipping of critical reagents to pharmaceutical manufacturing sites is likely, as are disruptions of finished pharmaceutical shipments to distribution centers and outbound air cargo.

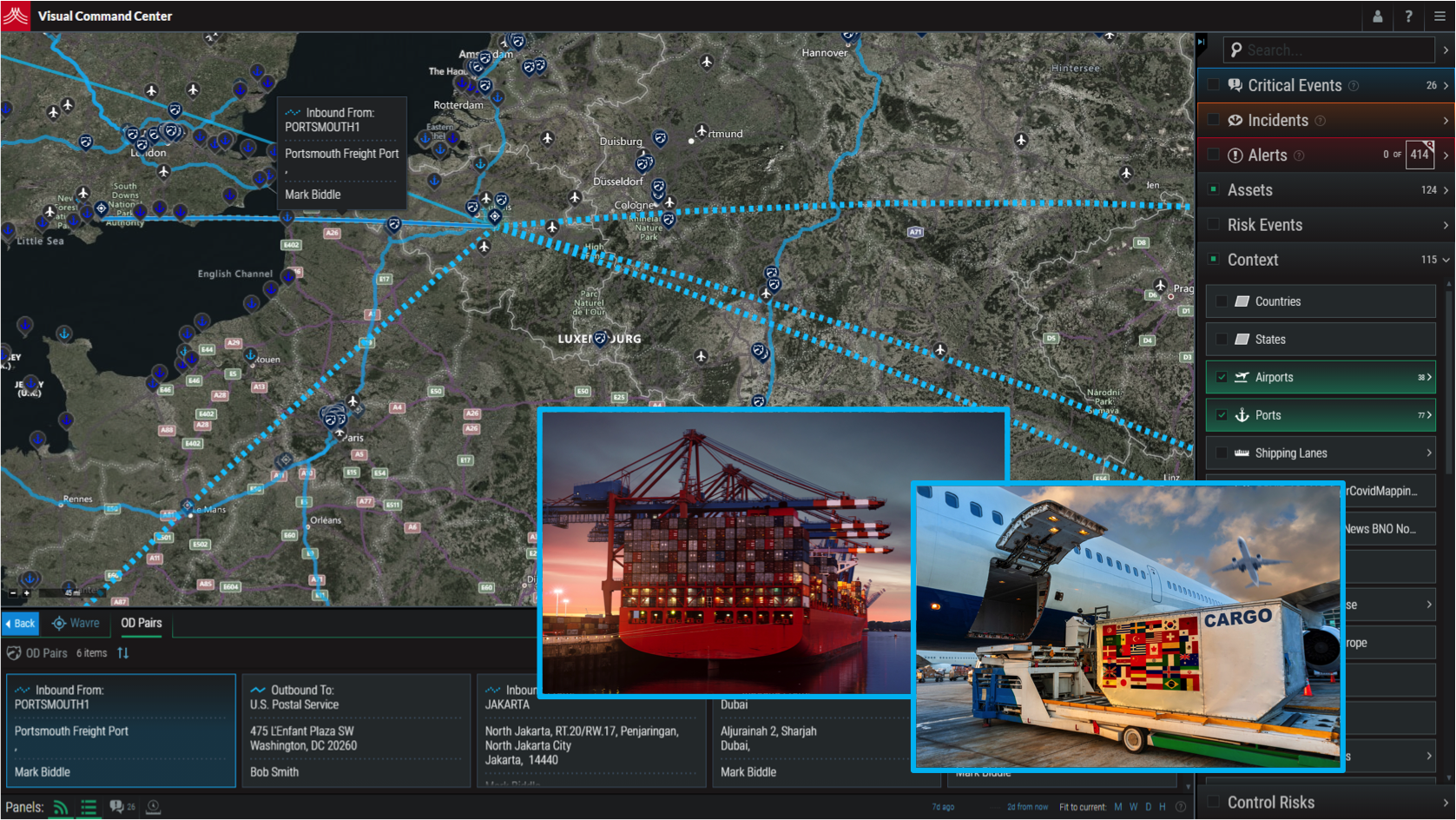

To understand which manufacturing and distribution sites may be affected, your team reviews the routes and Origin-Destination (O-D) pairs. The OD pairs help the team understand the dependencies of a manufacturing site to a supplier, and an outbound cargo departure site to a distribution center or other facility.

The supply chain operations team assesses the forecast at key locations. This includes the likelihood of road flooding, snow, and other elements that could impact transportation. The cargo is perishable and highly valuable – both are a concern in a major storm.

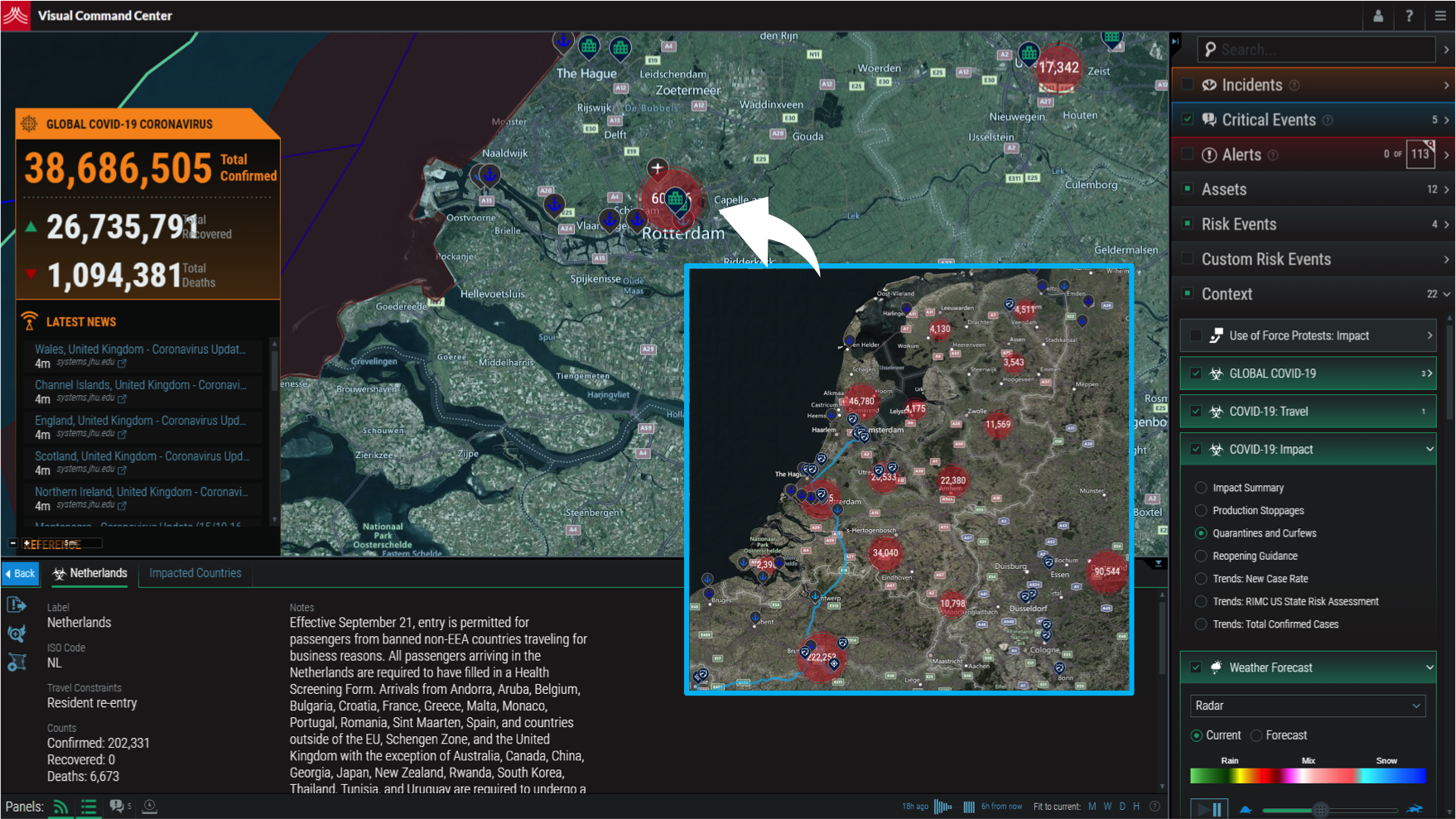

Live traffic conditions, live and forecast radar, and satellite images help the operations team understand where impacts are already being felt, where they will be felt (and when), and where shipments are able to continue as normal.

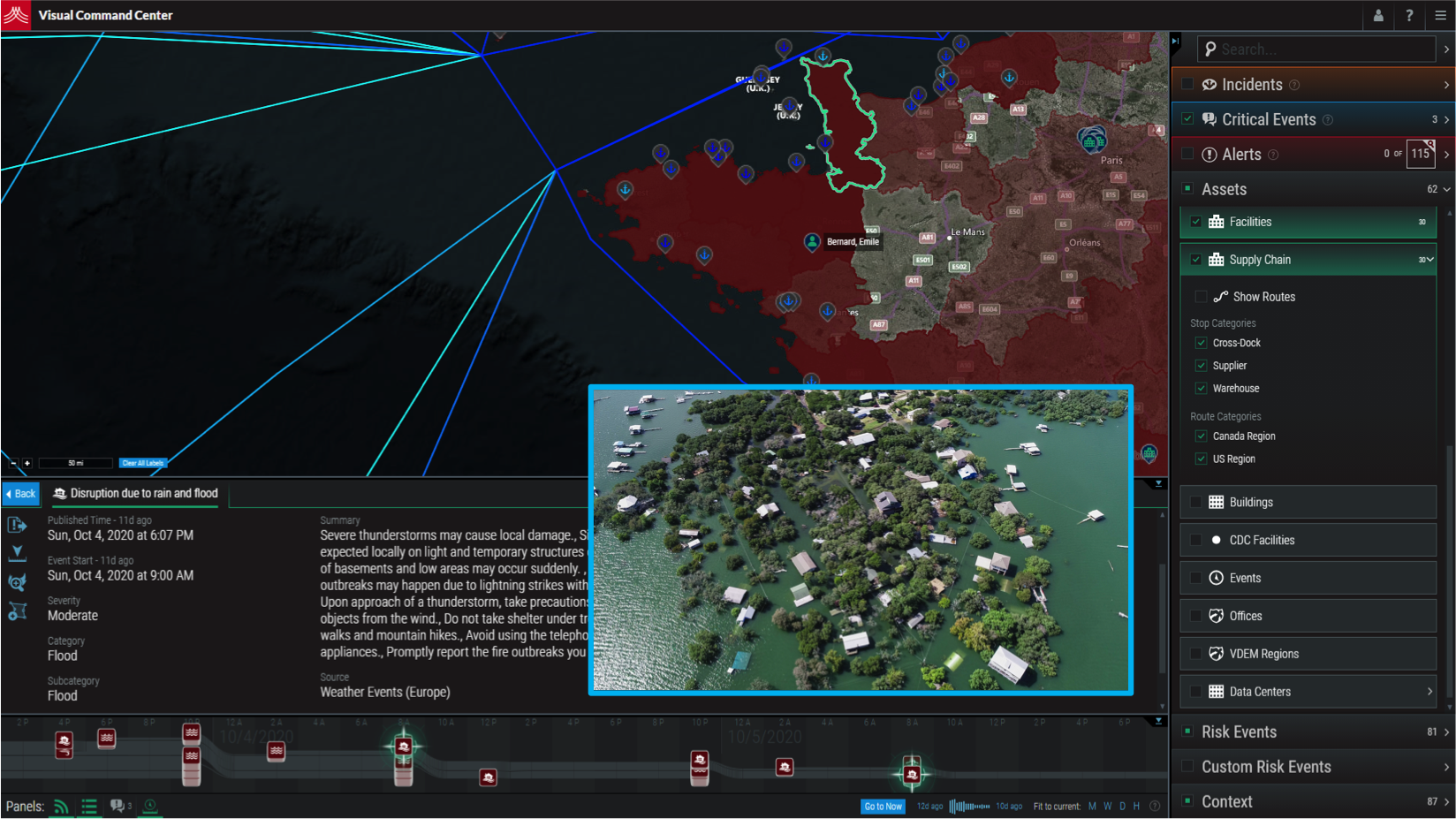

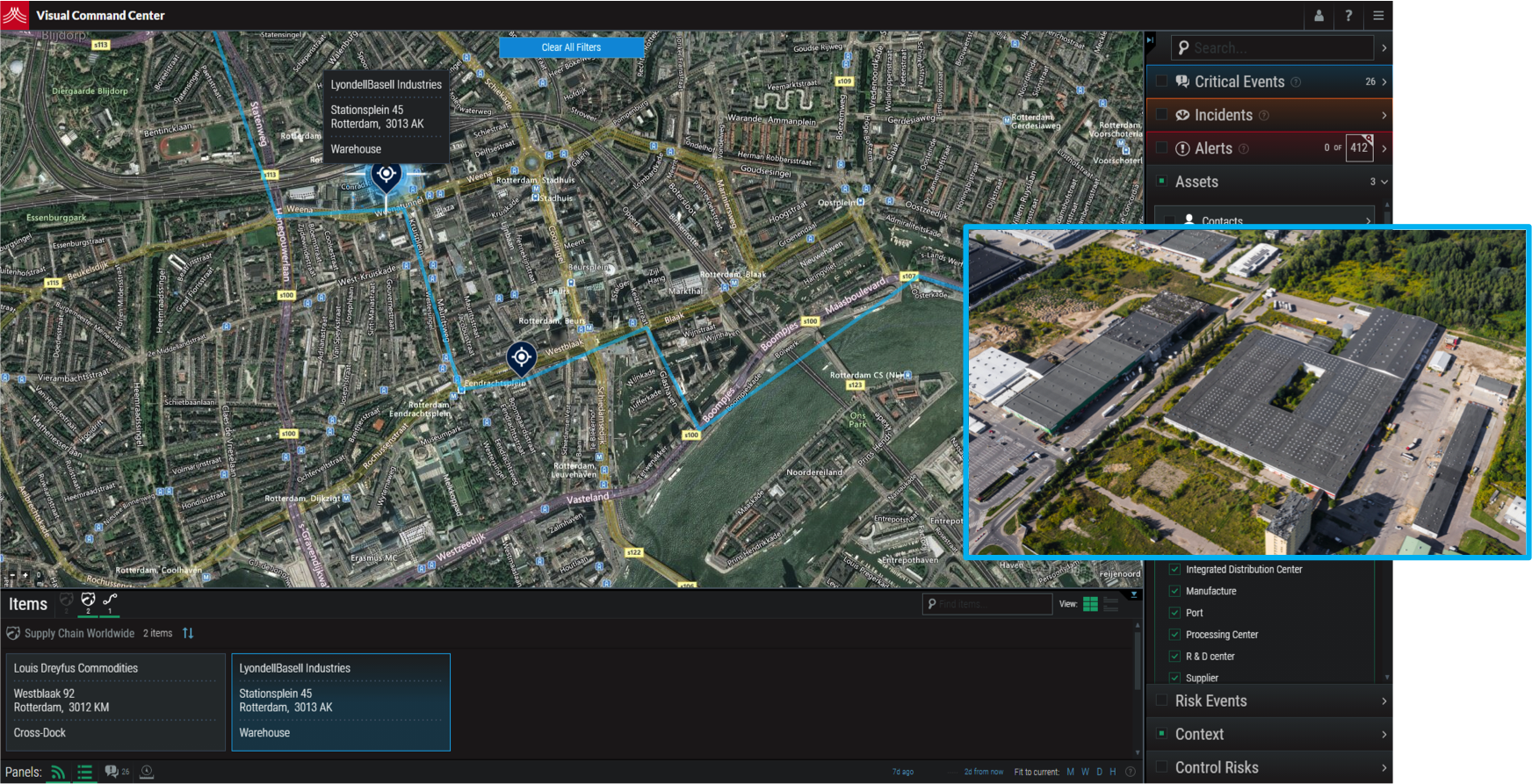

The supply chain operations team concludes that the risk of disruption is high, and alternate routes and temporary in-transit storage are required. Your team evaluates the disrupted routes and identifies nearby potential third-party sites.

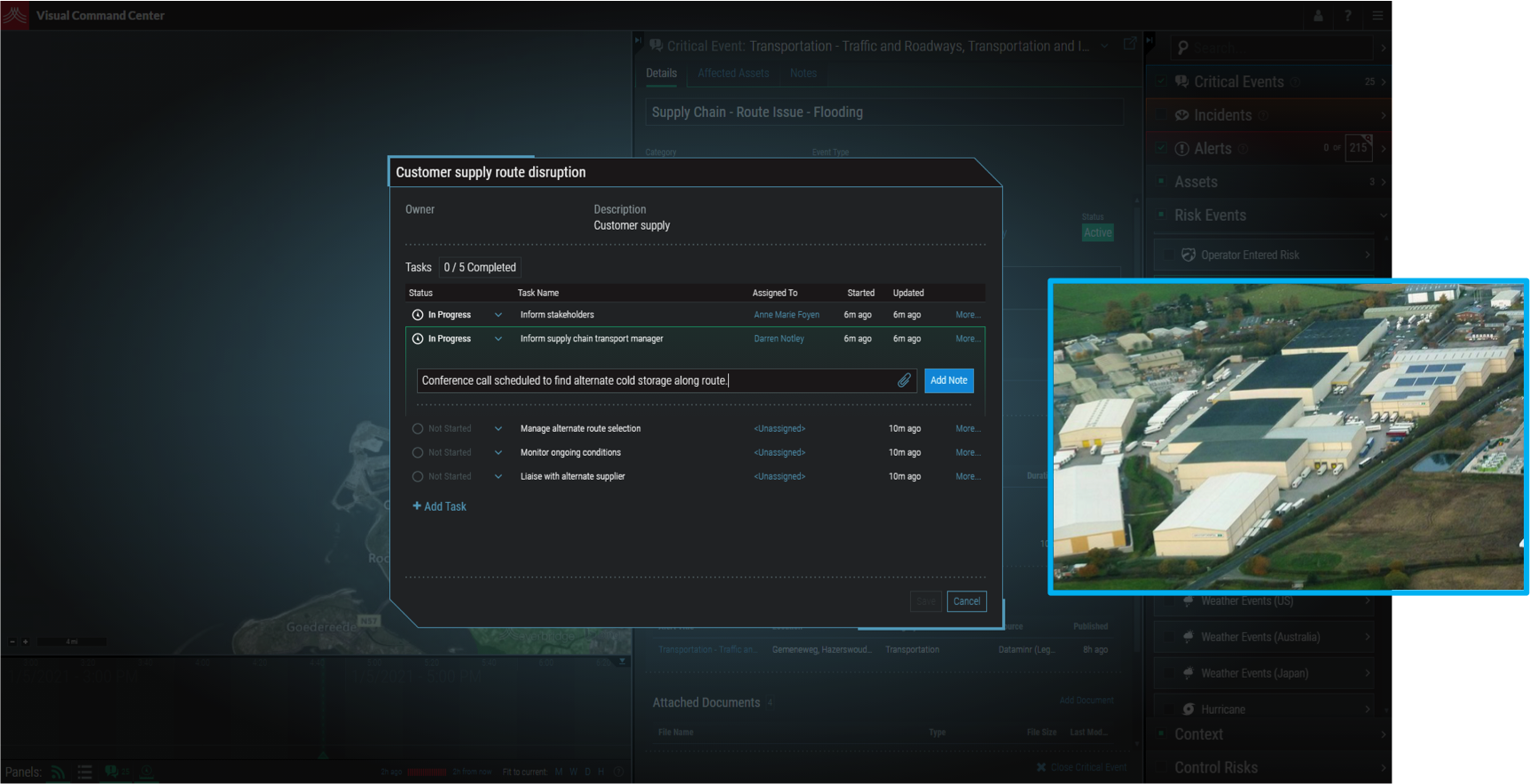

Timing is considered high priority, as third-party storage facilities are limited and book up quickly. The team needs to book them when demand is still low and less expensive. The team creates a Critical Event to manage workflows, communication, and collaboration.

The manufacturing operations and logistics teams monitor dashboards to understand the storm’s impact to warehouses, ports, roads and airports. These teams also join the conference call with supply chain operations to jointly review options and mitigation plans.

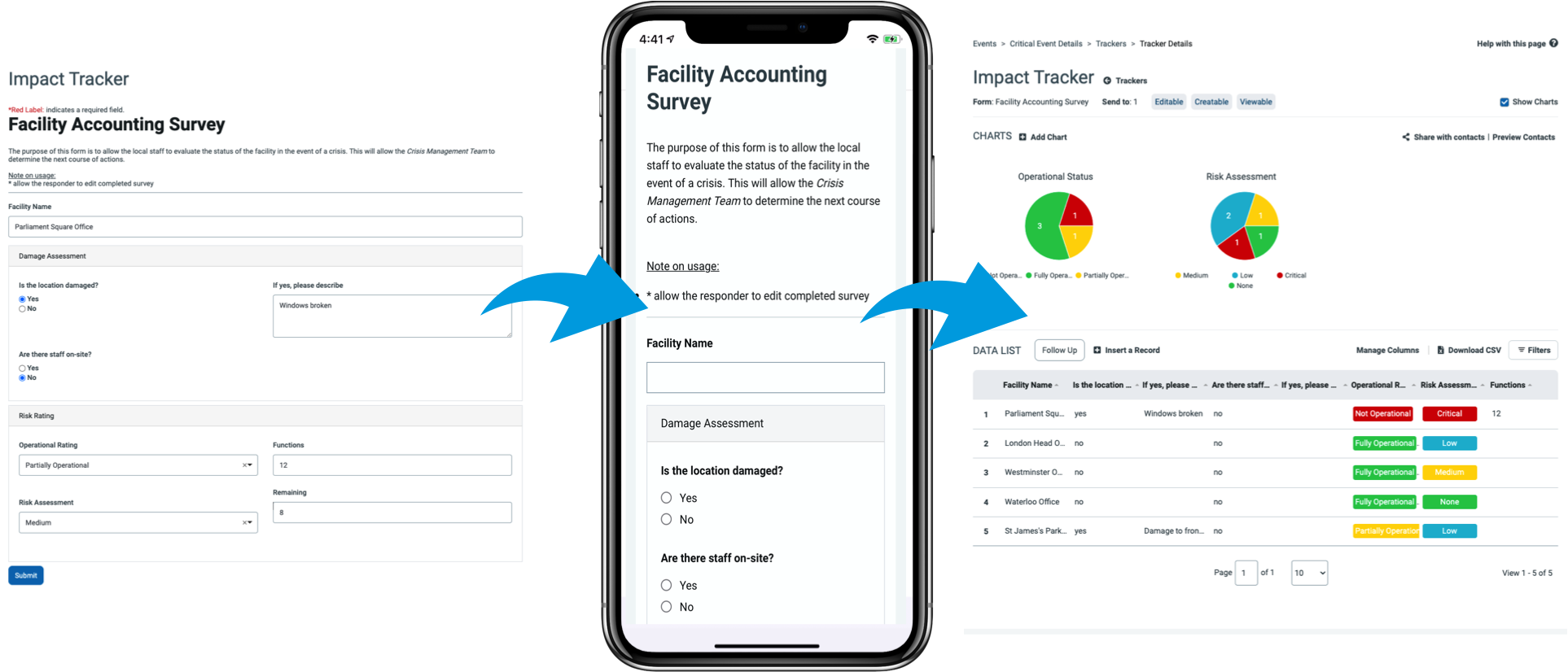

The operations team requests a status update from each location within the area to understand the impact of the weather on facilities, giving them a complete understanding of the business impact

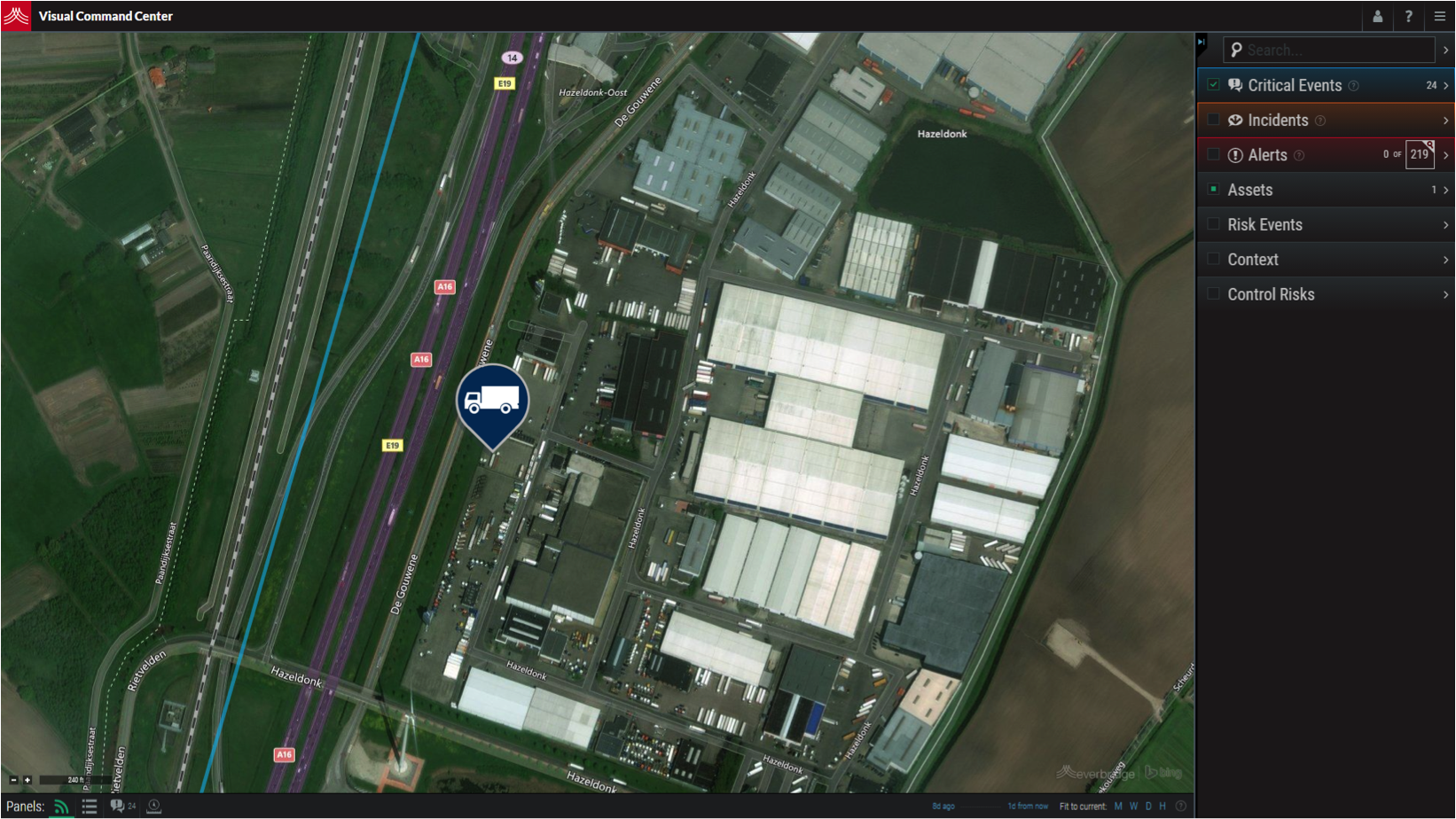

As the storm progresses and third-party storage locations are identified, Everbridge monitors updated routes for new risks or changes in the storm. If issues occur along any route or near any supplier, the supply chain operations team will be automatically notified.

The team also reviews new and updated routes for local conditions and compliance with COVID-19 restrictions on the movement of people and goods. This information is shared with drivers, so they know what to expect at third party storage facilities.

A driver stops for a break and fuel. He checks in with the Everbridge mobile application. He has opted in to provide location updates via the app, so the command center can advise him if he enters areas prone to the forecast flooding or other new hazards as they travel.

Using alternate storage and routes enables the team to bypass the worst hit areas and mitigate disruptions of these high-value shipments. Reagents arrive when expected and manufacturing continues uninterrupted.